|

Electro-Motive Division of General Motors Corporation in World War Two

LaGrange, IL

1930-2005

This page updated

8-17-2016.

Electro-Motive (EMD) originally started in

1922 in Cleveland, OH as Electro-Motive Engineering Company which

designed and built gasoline powered rail cars. In 1930

Electro-Motive Company, as it was renamed in 1925, and Winton Engine in

Cleveland were purchased by GM as it decided to get into the gasoline

railcar market. Winton was making a gasoline engine for

locomotives, and EMD was its prime customer its locomotive engines.

Right after that development of diesel engines by GM Research in 1934

lead to Winton in Cleveland beginning production of this type engine for

the US Navy and then later for locomotives. In 1941 the locomotive

diesel portion of Cleveland was folded into EMD and the equipment moved

to LaGrange, IL. Cleveland Diesel Division continued to make

maritime engines at Cleveland until the early 1960s.

In 2005 Electro-Motive was sold by GM

and is now known as Electro-Motive Diesel, is a wholly owned subsidiary

of Progress Rail Services Corporation with

its locomotive manufacturing facilities in Muncie, IN. Progress Rail

Services, itself owned by Caterpillar started production of locomotives

in 2011 in that location. It turns out the Muncie plant is only 13

miles from my residence.

According to the 1945 GM Annual Report, all

three of its Diesel Divisions, Cleveland Diesel, Detroit Diesel and EMD

produced a total of 198,000 engines for the US Army and Navy. It

would appear that EMD produced about 1,800-2,000 of those engines from

the data below.

Starting in November of 1939 and ending in

November of 1945 EMD produced 1,350 hp

V16-567 FT diesel locomotives. EMD was

the only company allowed to manufacture freight locomotives during the

war and they were built to assist the transportation of military

material. There were 555 cab equipped "A" units made and 541 cabless "B"

units for a total of 1,096 units and V16-567 engines produced.

This brings the total number of EMD diesel engines not including spares

manufactured to around 3,000 for World War Two.

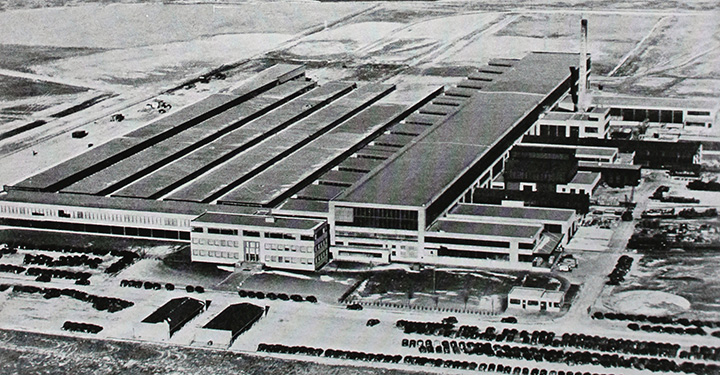

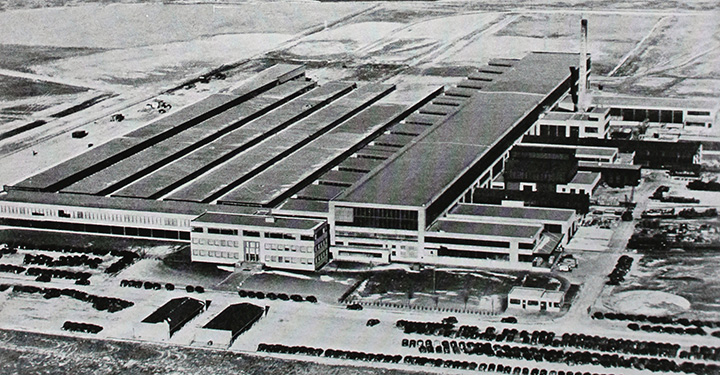

The EMD plant in LaGrange, IL just before

WWII in 1938.

Electro-Motive Division of General Motors World War Two Products:

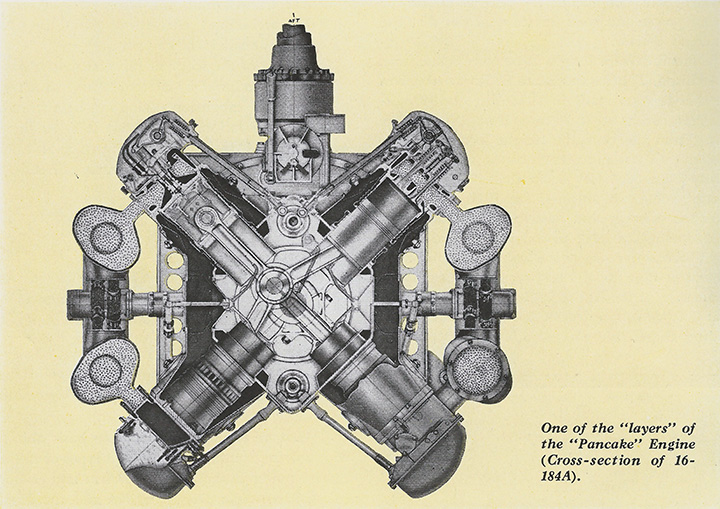

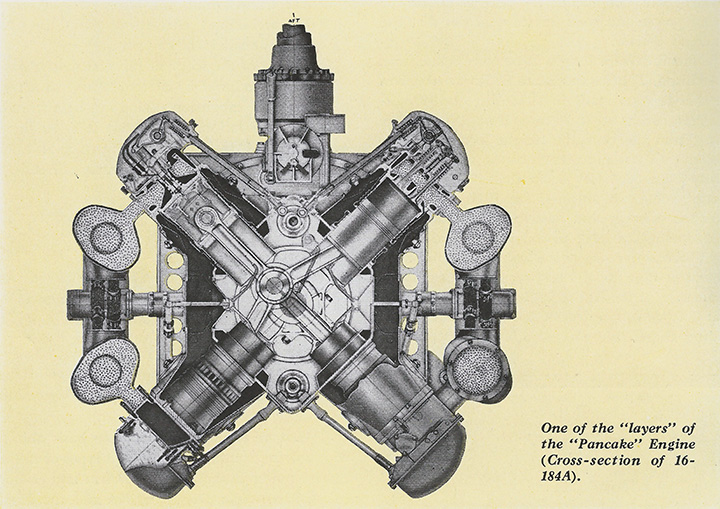

110 Foot Subchasers: (544) Pancake Diesel 16 cylinder 16-184A

Electro-Motive 1,200 hp for (243) 110 Foot Subchasers. The Pancake

engine replaced the heavier GM Cleveland Diesel 700 hp 8-268 engines and

increased top speed from 17 to 22 knots. This does not include any spare

engines. This was the only application of the pancake engine, due

to apparently frequent engine rebuilds and maintenance.

LSTs (Landing Ship, Tanks): Electro-Motive provided two

12-567 900 hp diesel engines for 525 LSTs. EMD

was one of the two manufacturers supplying engines for this ship. Fairbanks-Morse

supplied the other engines for the remaining 525 LSTs.

180 Foot PCE (Patrol Craft Escort):

(136) 12-567 900hp for engines 68 ships built with two engines

each.

Research indicates all 68 ships had the EMD engines.

Army DPC 86 foot Tugboats: (100)

8-567 Diesel Engines. Each tugboat had one engine and the DPC

stood for Defense Plant Corporation that ordered not only the tugboats

but barges and towboats for its use. Once the tugboats were

finished DPC found it did not need them as planned and many were turned

over to other organizations. Five went to the US Navy as YTs, (27)

went to the War Shipping Administration as WSAs and (21) went to the US

Army as STs.

LCI(L) (Landing Ship, Infantry (Large)):

(1,098) sets of reduction gears, propellers, drive shafts and

control units. Detroit Diesel built the Quad Four engine which

consisted of four twin 6-71 tank engines assembled into a single unit.

Two Quad Fours were supplied for each LCI(L).

Generators: (967) Delco Products

Division of GM 100KW generators for for uses on US Navy Landing Craft.

This work was taken over from Delco Products and the contract was

completed by mid 1943.

Locomotives:

Information available is inconsistent. EMD did build

locomotives during the Second World War to assist in the transportation

of war production. At the end of 1940 there were 617 EMD

locomotive units in service. At the end of 1942 there were 1,115

units in service giving a production of 498 for 1941 and 1942. No

information has been found on 1943 but in 1944 EMD produced 500

locomotives and had a production goal of 72 units per month or 864 per

year. This would take total units produced through 1943 to

1,615. The final data point is that as of 7-31-1947 there were

3,238 locomotives in service or 2,621 units produced from 1941 through

the middle of 1947.

Electro-Motive won the Army-Navy "E" Award five times during

World War Two.

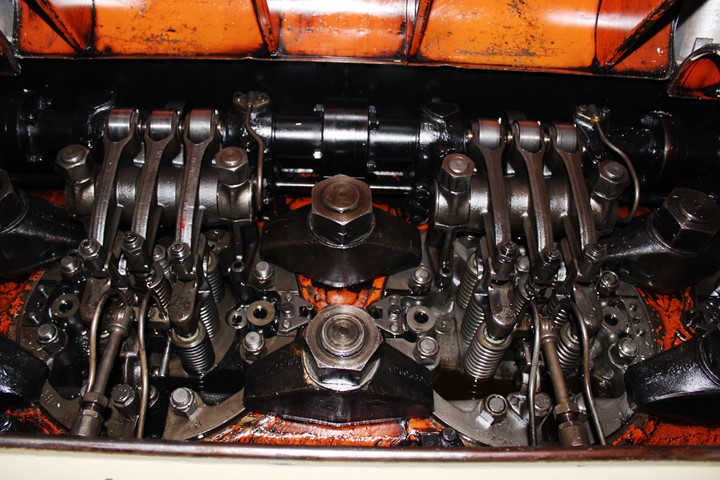

Inside the engine room of LST-393 are two

Electro-Motive 12-567ATLP/S (P=Port Engine and S=Starboard Engine) 900

BHP diesel engines. Both were built in 1942 when LST-393 was

constructed. This photo as the port engine nearest to the camera.

The starboard engine can be seen in the background.

The port engine.

The original data tag on the Electro-Motive

port engine on LST-393. The model number 12-567 indicates that the

engine has twelve cylinders, each on displacing 567 cu. in. or 6,804 cu.

in. of total engine displacement. Serial number N-132 was built on

October 20, 1942.

The starboard Electro-Motive engine on

LST-393. The engine was designed to be accessible to work on while

on the ship. The gray painted panels all give access to internal

engine components.

The starboard engine on LST-393 was also

built on October 20, 1942 and is serial number N-165. The model

number for this engine is 12-567ATLS. If one figures on the volume

of one cylinder, which is (3.14)(4.25**2)(10), one arrives at 567 cubic

inches.

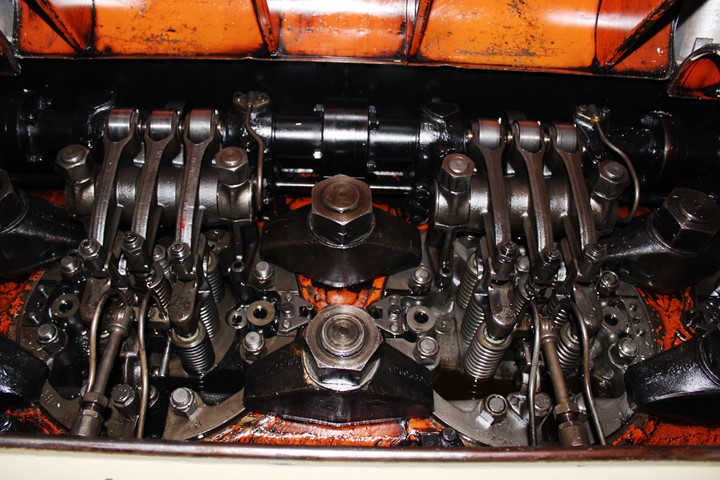

The valve covers can be lifted up and the

valve train examined and worked on.

The open shows access to the piston inside

the engine.

This photo looks at the starboard engine

from the output end. Each side of the engine has an air intake,

filter and supercharger.

This photo was taken standing next to the

supercharger and looking back at the gear Falk gear reduction unit and

the propeller shaft in the background.

In the LST the EMD 12-567 was connected to

the propeller with a Falk Marine Reversing Reduction Gear. This

reduced the higher output speed of the engine to one more suitable for

the propeller speed. It also allowed the propeller to run in

reverse. This was especially important when the LST needed to back

off the beach.

LST-325 is another one of the approximately 525

Landing Ship Tanks built during WWII that came equipped with two 12-567

900 hp Electro-Motive diesel engines. LST-325 is the last LST

still operating and she is seen here on the Ohio River in 2014.

Author's photograph added 10-12-2015.

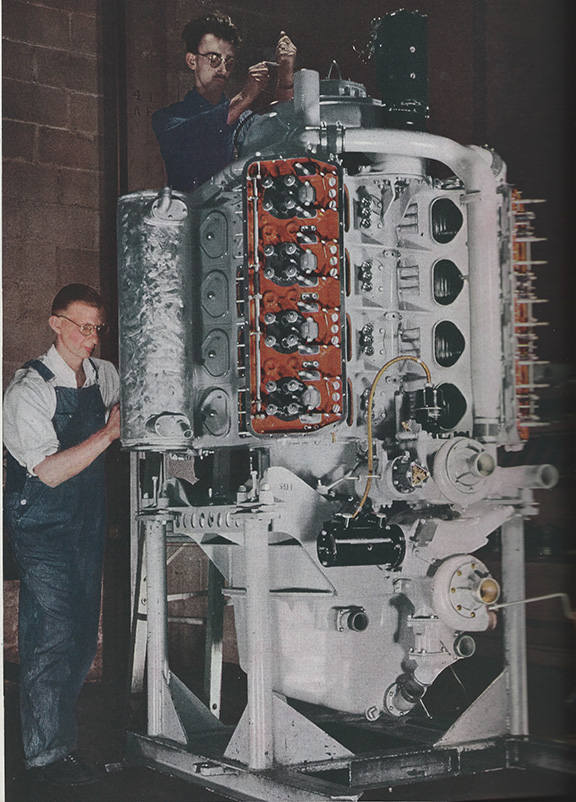

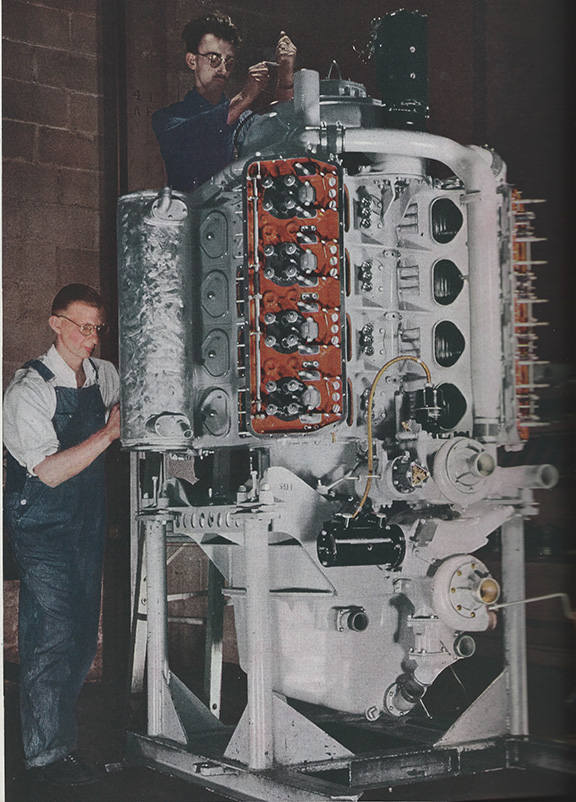

The Pancake engine under construction at EMD

during WWII. Output came out at a right angle to the engine at the

bottom.

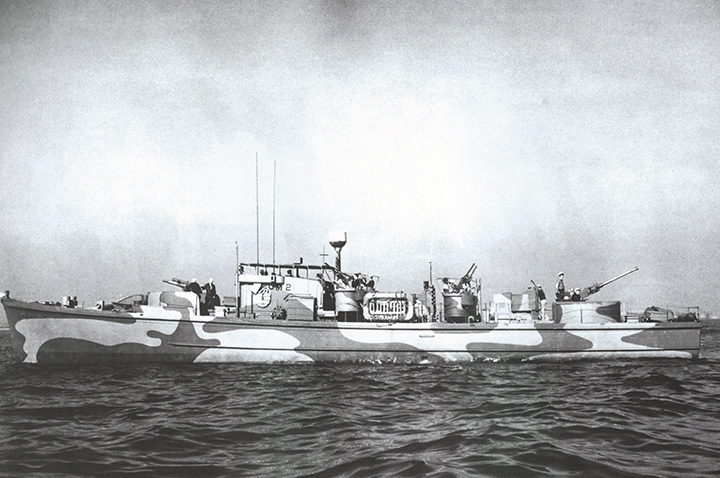

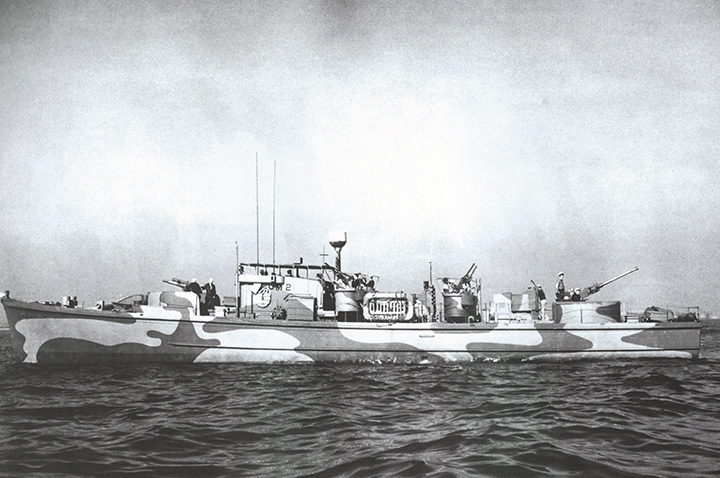

A 110 foot Subchaser during WWII which was

powered by two EMD Pancake engines.

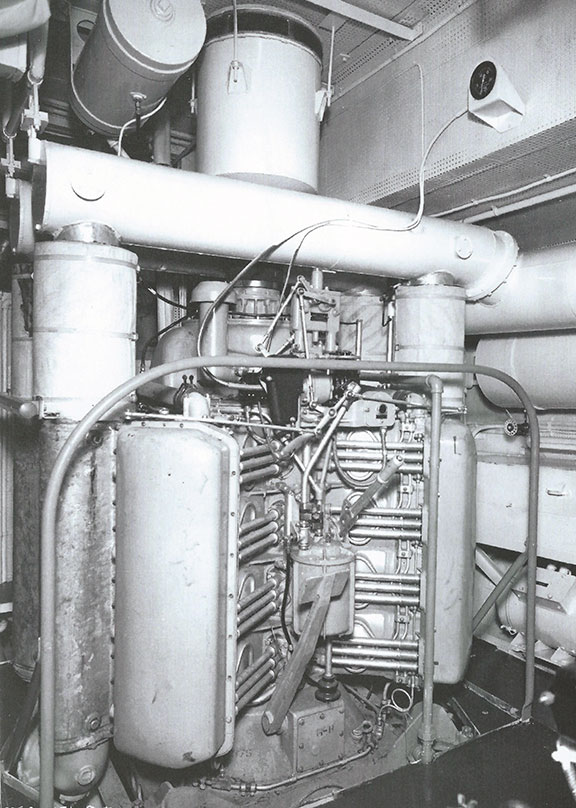

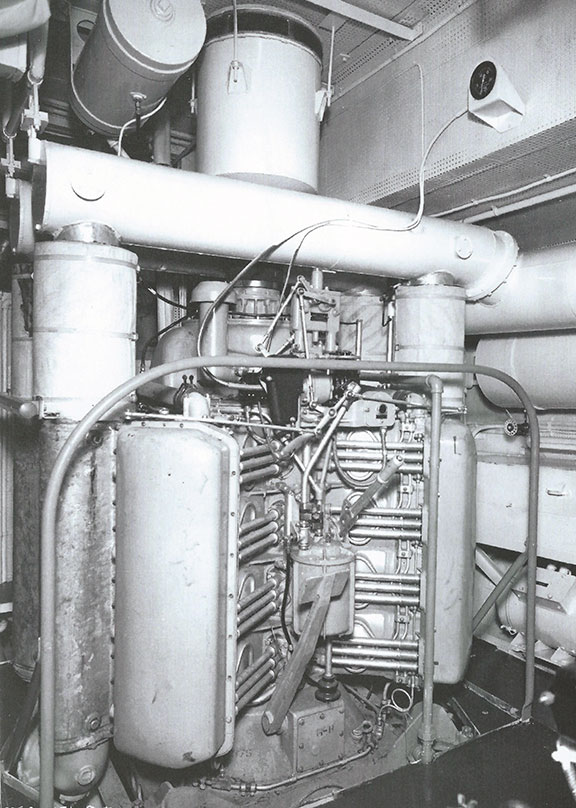

The EMD 16 cylinder 184A Pancake Engine in a

110 foot Subchaser's engine room.

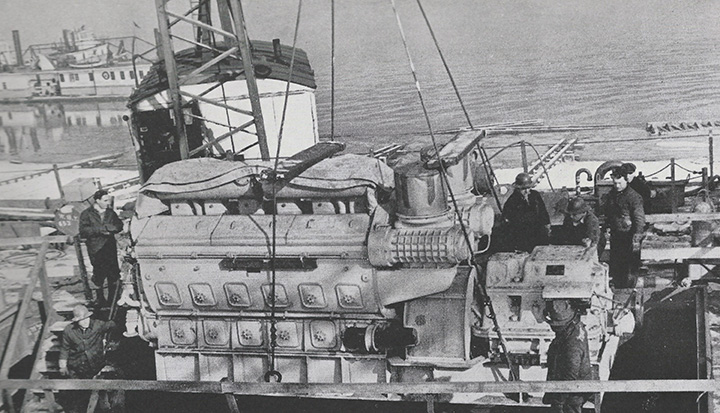

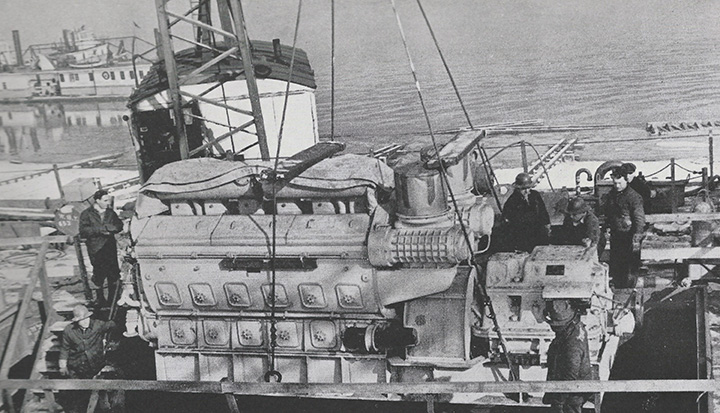

Here an EMD 12-567 900 hp diesel engine is

being installed in an LST during WWII.

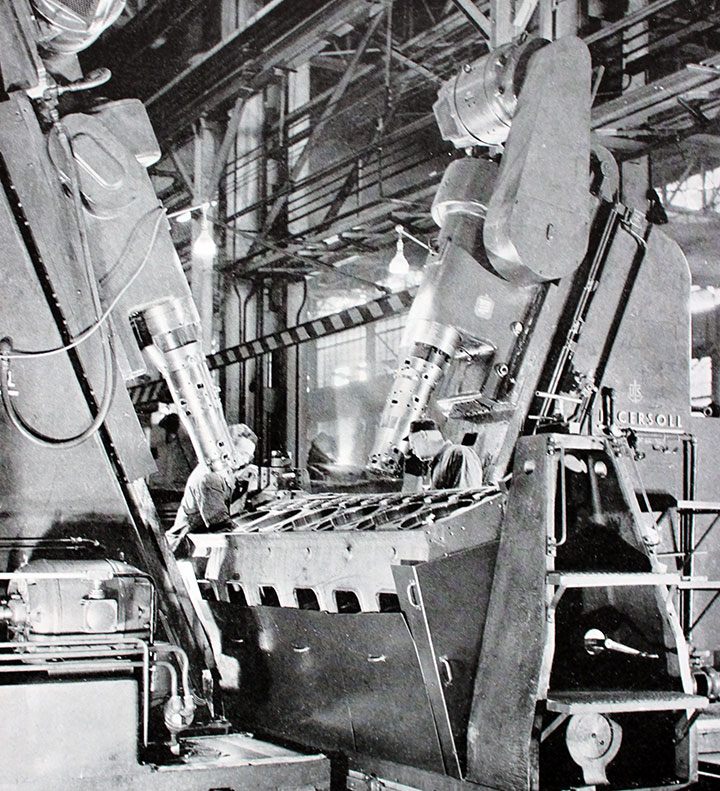

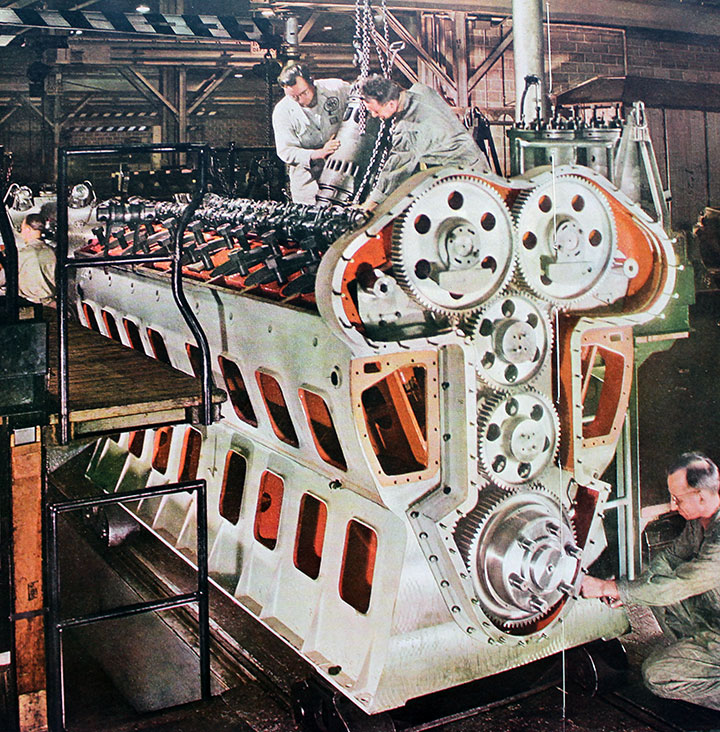

EMD 12-567 900 hp diesel engine blocks being

worked on during WWII.

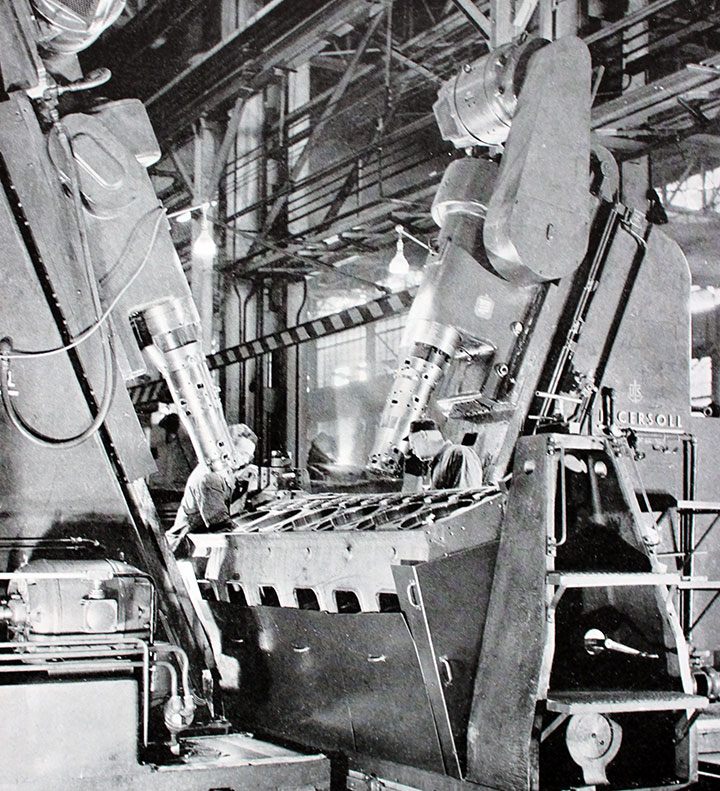

Here an EMD 12-567 engine block is being

machined.

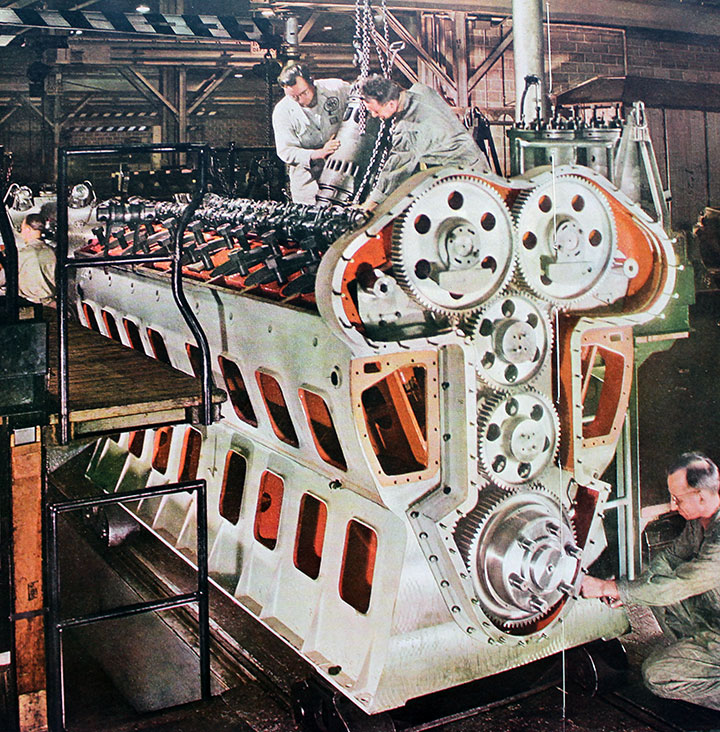

Final assembly of a

EMD 12-567 in LaGrange, IL during WWII.

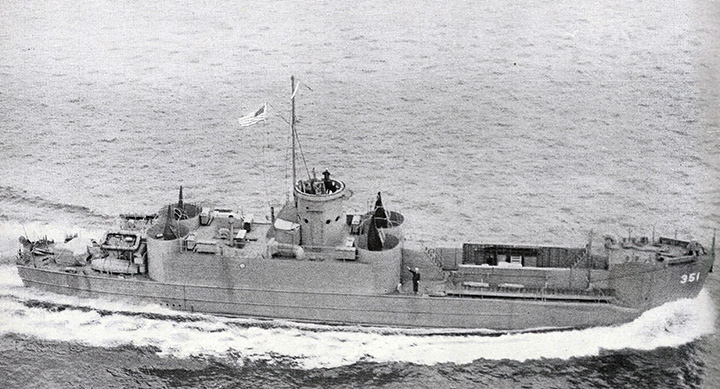

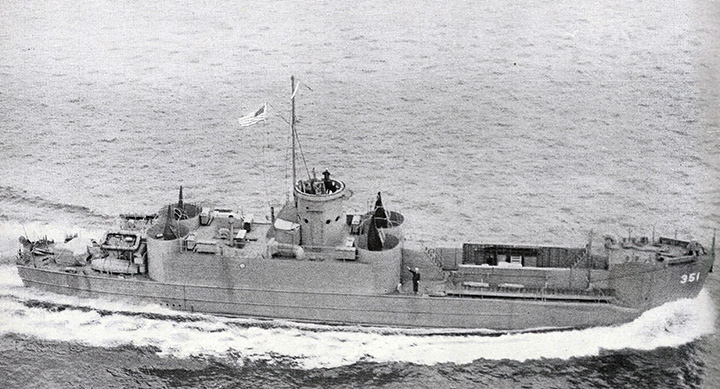

A US Navy LCI(L) (Landing Ship, Infantry

(Large)) underway during WWII with EMD supplied reduction gears,

propellers, drive shafts and control units.

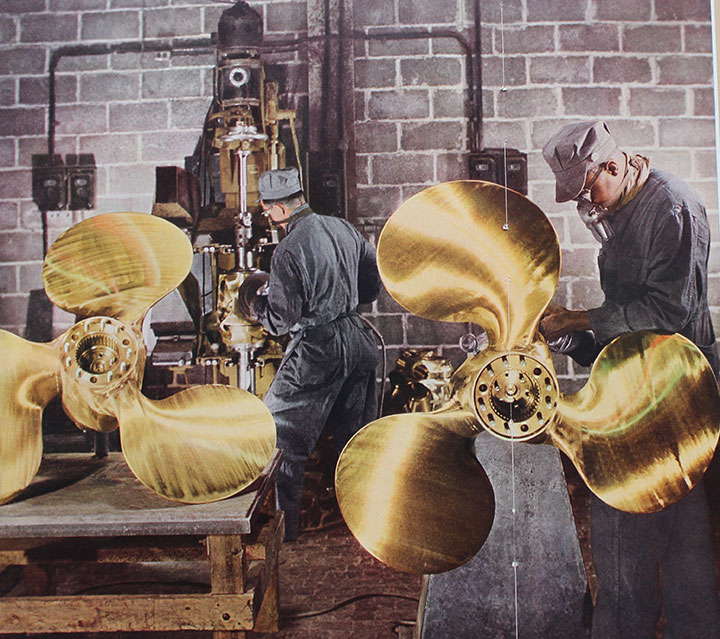

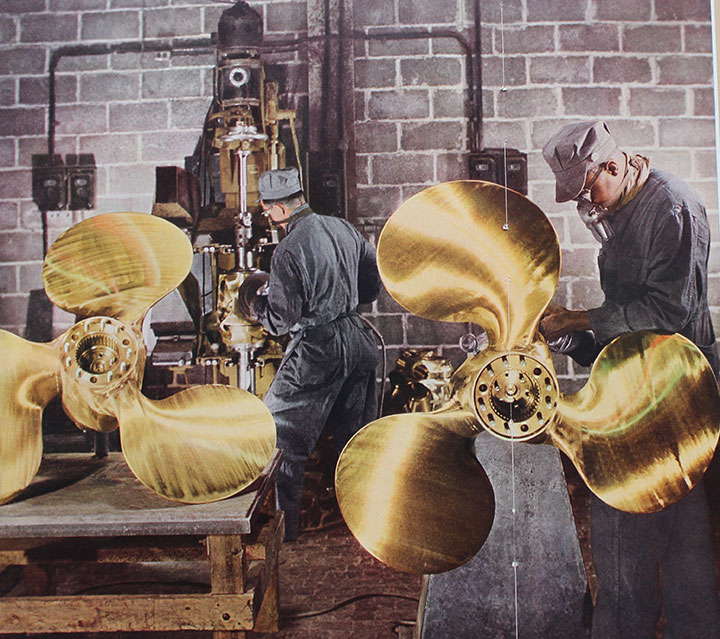

Final balancing and polishing of the LCI(L)

propellers by EMD workers during WWII. EMD supplied 2,190 brass

propellers like this for the landing craft.

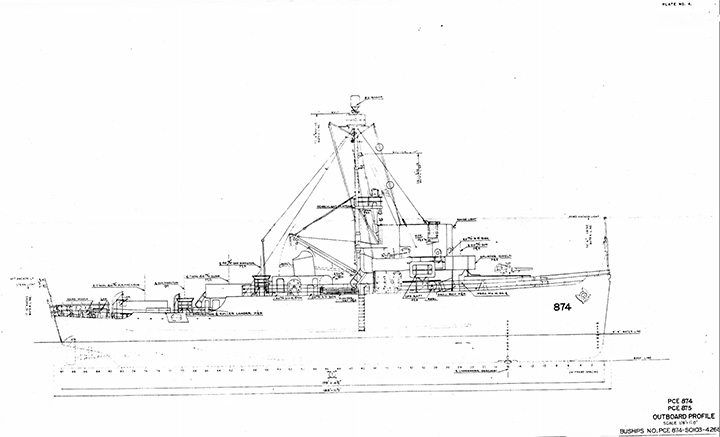

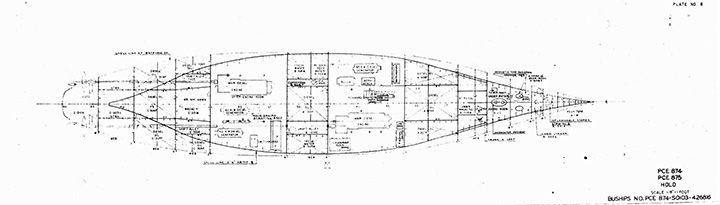

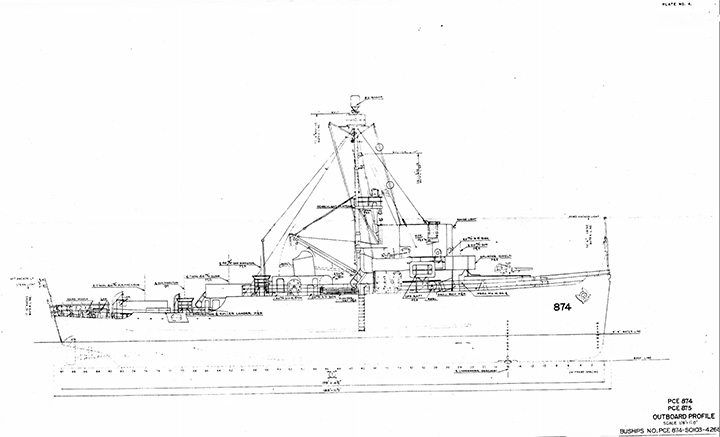

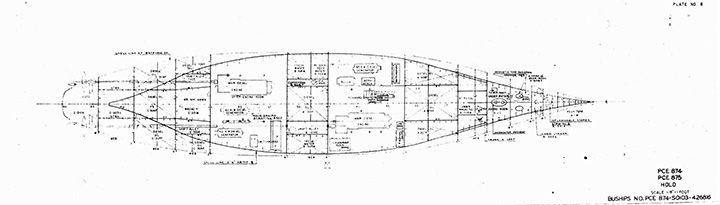

An outline drawing of a 180 foot Patrol

Craft Escort.

This drawing the 180 foot PCE shows the

location of the two EMD 12-567 900hp diesel engines.

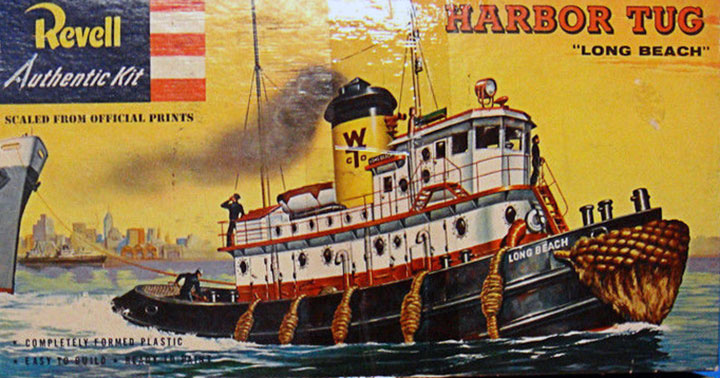

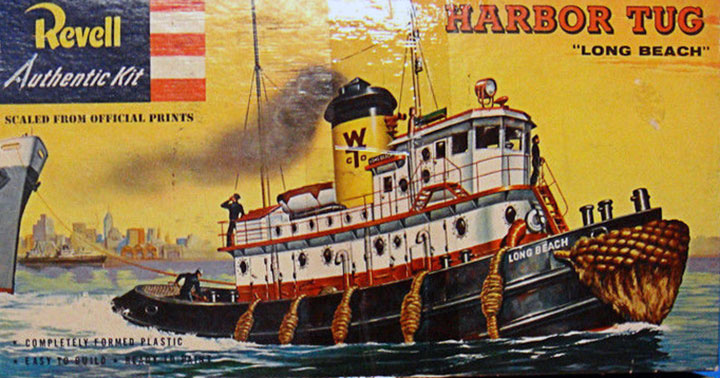

It turns out as a boy growing up in the late

fifties, I built the Harbor Tug "Long Beach" after receiving it as

either a birthday or Christmas present. It turns out the "Long

Beach" was built in Decatur, AL in 1944 as DPC 68 with an EMD 8-567

Diesel Engine. It was then turned over to the War Shipping

Administration as WSA 26 and then sold as surplus in 1946.

This a 1955 EMD F unit which is very similar

to the World War Two era FT units it produced. Author's photo at

the Colorado Railroad Museum.

This photo shows better both the cab

and cabless booster units. Author's photo at the Colorado Railroad

Museum.

This not only shows it is a 1955 model

but more important the EMD name tag. Author's photo at the

Colorado Railroad Museum.

|